Ferries of the future save 65% carbon dioxide

In the strait between Denmark and Sweden, two ferries are leading the way to tomorrow’s marine transportation.

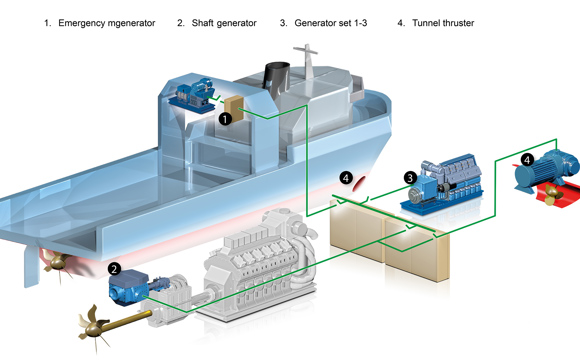

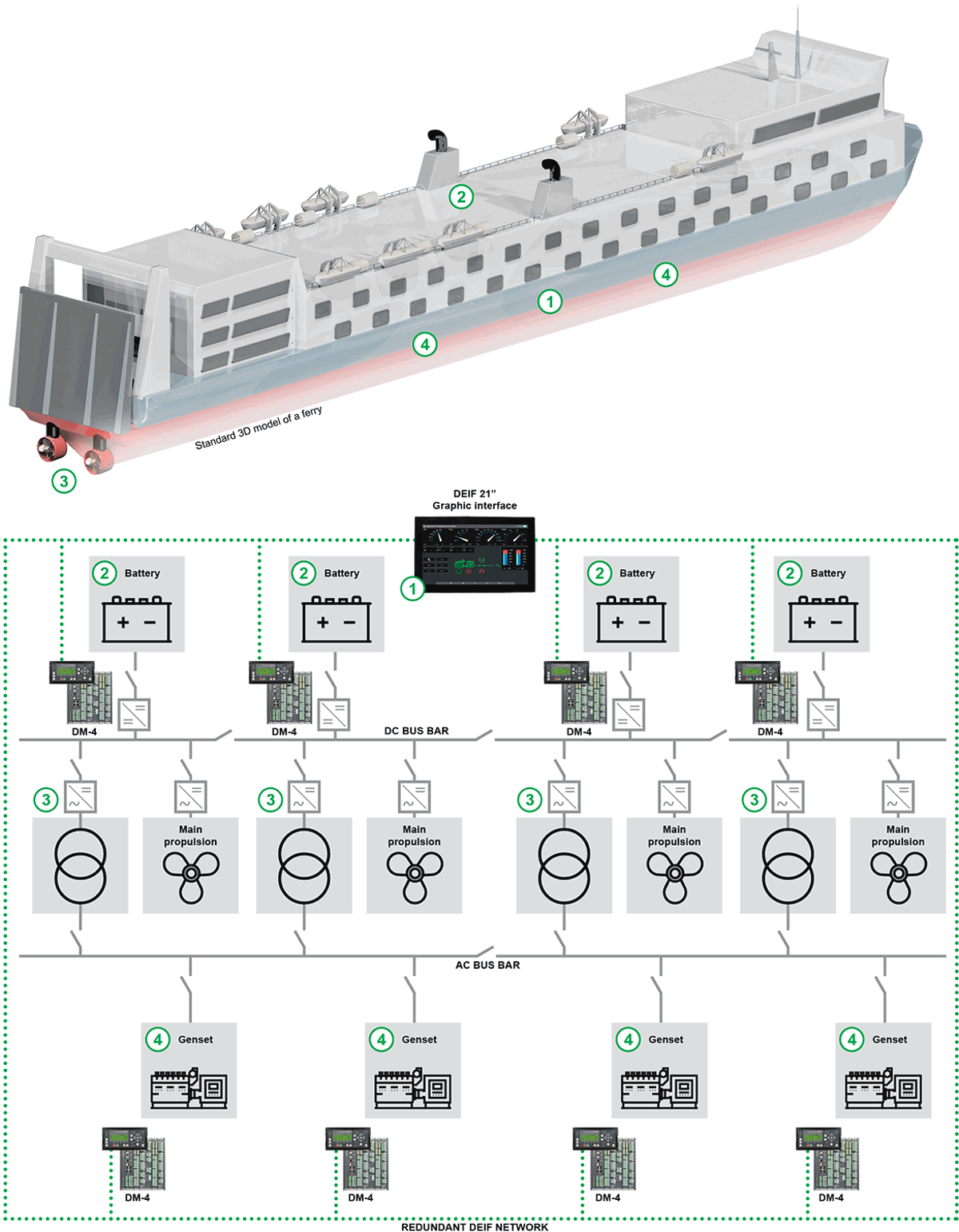

In a major project co-financed by the European Union, the M/F Tycho Brahe and M/F Aurora are still equipped with their original diesel-powered engines, but four containers on each top deck hold the equivalent of about 4160 kilowatt hours (kWh) of electrical power: 640 lithium batteries, with 11 megawatt (MW) total. Charging is done with up to 11 MW.

The ships can run on full battery, full diesel or a combined, hybrid set-up. They are two out of four ferries running the busy route between Elsinore (Helsingør), Denmark, and Helsingborg, Sweden, a yearly total of 50,000 times – and with 7.2 million passengers. The ships’ owner, ForSea, thus saves 65% CO2 emissions on its battery-sailed initiative.

“We would really like to be a green shipping company, and we want to do something for the environment,” says Henrik Fald Hansen, Senior Chief Engineer on the M/F Tycho Brahe. “This is our contribution.”

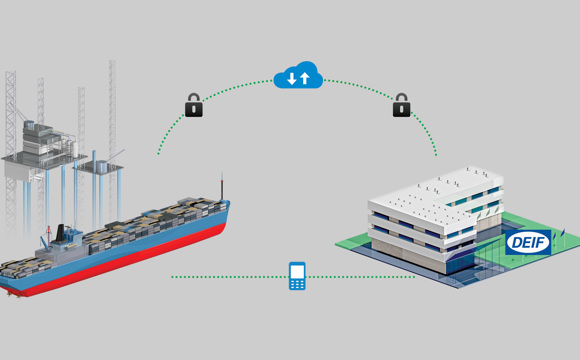

The ferries charge the batteries with electricity coming from renewable-generation in Denmark and Sweden – such as wind, hydro and solar. Thus, when the ferries run on battery power alone, they are nearly 100% CO2-free, says Henrik Fald Hansen. They both use DEIF Delomatic 4 systems for power management.

“These are the ferries of the future,” he says.

Three modes with DEIF

When ForSea was re-tooling the ships with batteries in 2017, it needed a power management system that could handle the three operating modes: diesel, battery or hybrid. Tycho Brahe was already running with a DEIF power management system since 2013, so DEIF was to upgrade that to a Delomatic 4 for diesel-electric propulsion.

A diesel, “old-fashioned” mode simply operates gensets and main propulsion the usual way, says Per Ole Sørensen, Team Manager in DEIF’s Marine & Offshore System Solutions Department. The power management system calculates and controls the load onboard the vessel, telling the main propulsion how much power is available.

A battery-powered operation must work similarly but collects data from the batteries’ own management system. It calculates how much discharge capacity is available and the max power needed, again making sure the main propulsion is not overloading the system.

“We have been really, really satisfied in the way the DEIF system handles problems for us. We trust it.”

Henrik Fald Hansen

Senior Chief Engineer | M/F Tycho Brahe

And then the ship’s operator – or the system itself – can initiate the hybrid mode. If the energy level in the batteries is low, then it must start up a diesel genset and operate in parallel with the batteries. The main propulsion can even charge the batteries until the ship reaches harbour.

Hybrid ferries save 65% carbon dioxide

The batteries on board can propel the Tycho Brahe more than two times between harbours, but the ship recharges every time.

“We are on the world’s largest battery-powered ship,” Henrik says. “We recharge with 10-11 MW at harbour with high-voltage lines.” When the ship comes to dock, a robot arm carefully “plugs in” the high voltage line to the side of the ship. “We have five and a half minutes to charge in Denmark and nine minutes to charge in Sweden – so it’s got to go quickly.”

ForSea Ferries has installed a double (redundant) safety and emergency protection system, which includes a water-cooling system for the batteries and aerosol and water sprinkler systems for the containers, he says.

Side benefit: Quiet

When the Tycho Brahe sails on battery power, the engine room is quiet.

“It’s a completely different working environment,” says Henrik Fald Hansen. “It’s a strange feeling as a mechanical engineer to have a machine room that’s quiet. The first time we stopped the diesel motors and sailed on battery, the hair on my arms stood up. It’s fantastic. It’s so impressive to see that batteries can power so large a ship. We get a completely peaceful and quiet place to work."

“This is an innovative project,” he adds. “Electrical propulsion is the future. I’m proud to be a part of the world’s largest battery-driven ship, and part of such a large project. It has been a lot of work, but there are so many things we can be proud about.”

DEIF supplied:

DEIF supplied a Delomatic 4 power management solution and AGI touch panel to the M/F Tycho Brahe and M/F Aurora ferries for hybrid diesel-electric propulsion.

Not just power. Energy

“With the batteries, you have more of an ‘energy management system,’” Per Ole says. “It’s not only the power anymore. Your system has to be able to monitor the energy left in the batteries. Are we going to use all that energy in a moment? Then it will start up a genset and run in hybrid mode.”

Henrik Fald Hansen says that when the Tycho Brahe installed the previous DEIF system in 2013, the ship’s crew had to get used to it. “Could we rely on it? We have just been really, really satisfied in the way the DEIF system handled problems for us. We could trust it. If there was a generator that wouldn’t start or something like that, the DEIF system took care of it. And we’ve had the same feeling after installing the batteries and new DEIF system. We have definitely been confident that DEIF can handle things when there are any problems.”

-

Contact us to discuss your options

- 90 years of energy pioneering

- Manufactured at the highest standards

- Superior quality

- Unmatched service and support

- Made in Denmark